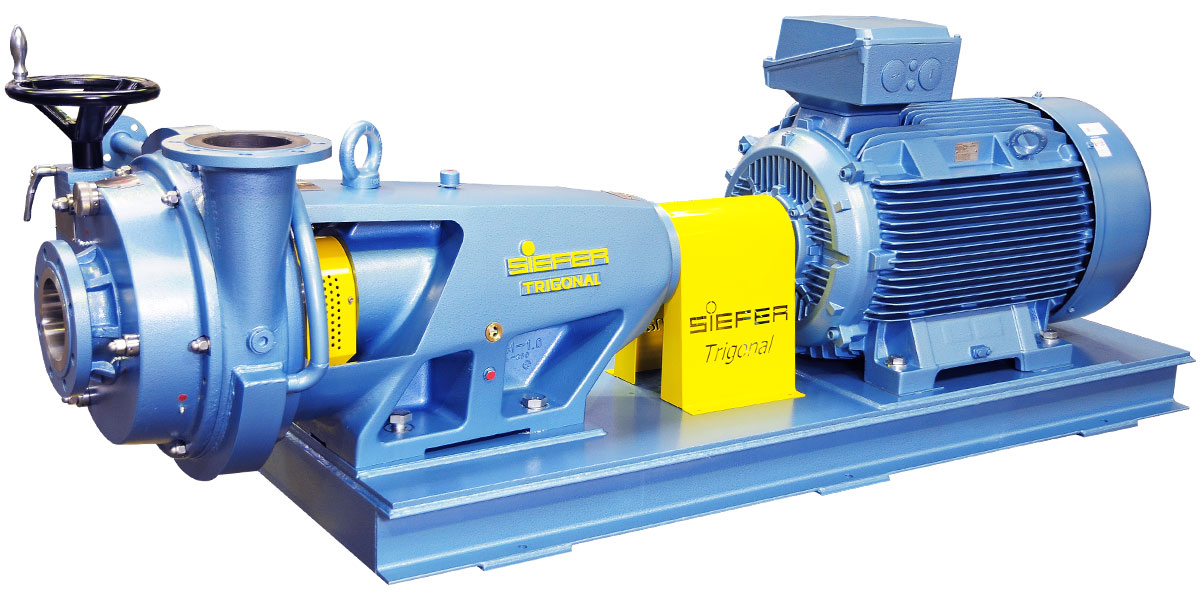

The functioning principle

The operating principle of the Siefer Trigonal® machines is simply genius. Our machines can reduce the size of solid materials with various wet processes in order to join and merge them with a second, liquid component.

This is how it works

After filling a Trigonal® machine, the source material is reduced in size by a system of up to four coaxially arranged, rigid and movable rings. That is the Trigonal® principle.

This rotor-stator system can reach speeds of up to 4,500 revolutions per minute. The material is reduced in size and/or mixed with a second component by means of grooves, blades and/or drills.

Customised for all tasks

There is a large variety of options for assembling the machines: the number of rings, their shapes, and their dimensions can be set up individually and optimally adapted to different tasks. Equipping the machine with a cooling or heating jacket increases the temperature range during processing and extends the scope of application even further.

This guarantees a wide variety of application possibilities in almost all industrial sectors.

From pharmaceutical manufacturers to the food industry and recycling processes – Siefer Trigonal® machines are used wherever size reduction and/or mixing of materials are required: during homogenisation, emulsification, dispersion, polymerisation, deagglomeration, neutralisation or extraction.

Highly sophisticated

Despite their simple operating principle, Siefer Trigonal® machines are highly complex constructions. They lead the market thanks to their design, processing quality, and the precisely aligned components, and are used worldwide.

In over 6,000 processing plants – for more than 50 years.