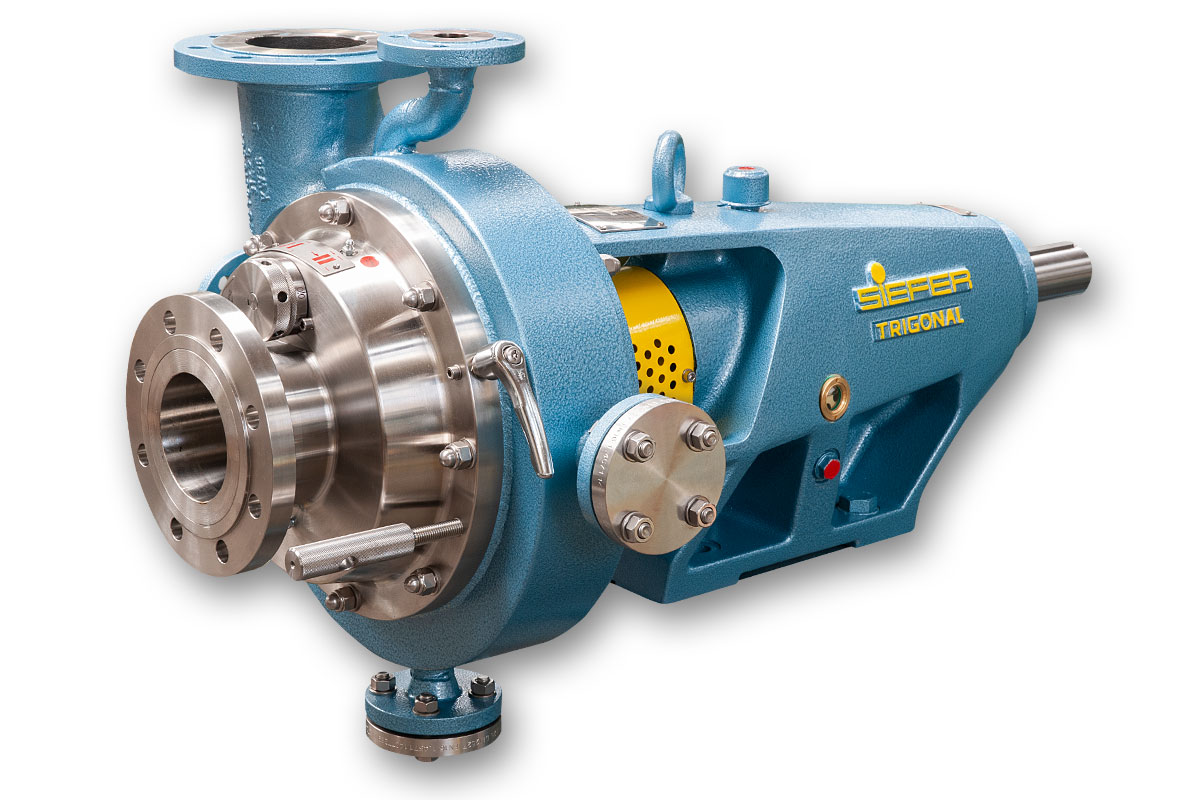

The Siefer Trigonal® machine SM 290 / SM 290 HK (heating/cooling jacket)

The SM 290 can be used variably in many sectors – whether it is agrochemicals, food, the paper and recycling industry, or paints, animal feed and cosmetics. The machine weighs either 265 kg or 275 kg (with heating/cooling jacket) and is characterised by its extremely compact construction in relation to its performance (1,000 x 500 x 500 mm and 1,000 x 580 x 580 mm with heating/cooling jacket).

Lower speed, powerful drive

Compared with the SM 180, the SM 290 impresses with its more powerful drive: with comparatively low rotation speeds between 1,500 and 3,600 revolutions per minute, the machine generates an impressive 110 kW of drive power. The result is a high throughput: 120 cubic metres per hour (based on water) are possible. Handling particle sizes of up to 5 mm in diameter is no problem for the SM 290. It has a high performance potential that will make your production future-proof.

Are you interested in the SM 290/ SM 290 HK?

Then please feel free to request the datasheet and further information

at info@siefer-trigonal.de.

Technical data

Characteristics of the SM 290

| SM 290 | SM 290/HK | |

|---|---|---|

| Throughput based on water [m³/h] | 6 – 120 | 6 – 120 |

| Discharge pressure [bar] | 6 | 6 |

| Drive power [kW] | 15 – 110 | 15 – 110 |

| Connections at suction/discharge side DIN / ANSI | 100 (4″) | 100 (4″) |

| Rotation speed min./max. [min -¹] | 1.500 – 3.600 | 1.500 – 3.600 |

| Max. feed size for solid/dry matter [mm] | Ø 50 | Ø 50 |

| Dimensions L/W/H [mm] | 1.000 x 500 x 500 | 1.000 x 580 x 580 |

| Weight [kg] (without accessories) | 265 | 275 |

- A selection of different materials for parts in contact with the product

- Drive takes place via coupling or V-belt

- Various alignments of the discharge port

- Large selection of possible shaft seals in cartridge design

- Flange connections in DIN or ANSI

- Binary feed for merging of different partial flows

- ATEX version

- Excellent accessibility and exchangeability of the cutting tool

- Quick replacement and RESHARPENING of the tool system

- Very high availability, long service life and durability of the machine

Bitumen and

bitumen

emulsion

Chemical

industry

Agrochemical

industry

Food

Animal feed

Bitumen and

bitumen

emulsion

Chemical

industry

Agrochemical

industry

Food